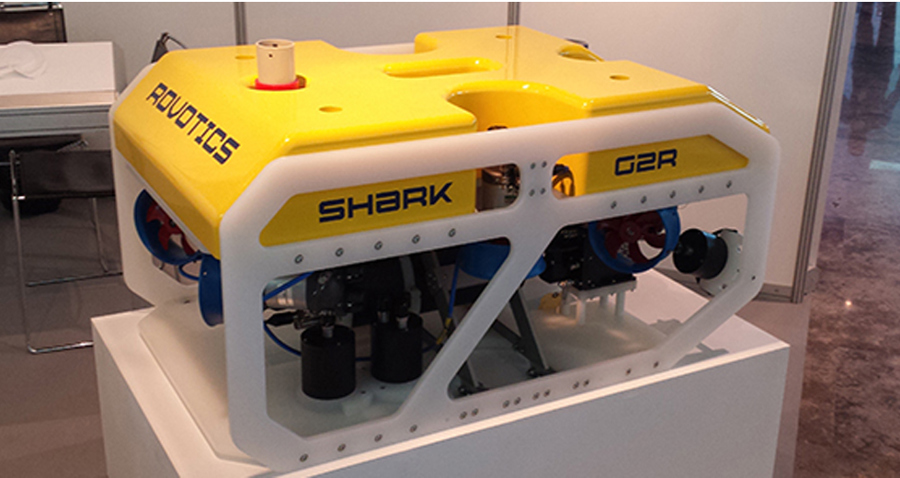

The Shark G2R from Rovotics is a reliable and cost-efficient Remotely Operated Vehicle (ROV) designed for surveying various subsea assets. In order to achieve the professional finish needed for the vehicles, Diab provided Rovotics with complete, 5 axis CNC processed and painted foam buoyancy kit just to bolt-in-place.

Sub headline

A Remotely Operated Vehicle (ROV) is an underwater vehicle controlled from the surface. Being highly maneuverable and able to provide video and still camera imagery along with information from various other sensors it allows observing, inspecting, mapping and measuring the condition of subsea assets.

ROVs were first developed for industrial purposes, such as inspection of pipelines and testing the structure of offshore platforms. However, today ROVs are used for many applications, many of them scientific.

Designing for buoyancy and stability

ROVs are usually designed to have positive buoyancy, i.e. to float on the surface, to ensure they will return to the surface if a power failure occurs. Desired buoyancy and stability are achieved using Divinycell PVC foam and an accurate prediction of net buoyancy is invaluable in the design process. Without it, the designer risks making guesses that may require time-consuming and expensive alterations or complete rebuilds.

Shark G2R – a reliable seahorse

The Shark G2R is a ROV designed and manufactured by Rovotics. Headquartered in the United Arab Emirates, Rovotics specialize in cutting edge, highly dependable ROVs and components including cameras, lights, junction boxes, subsea housings and CP equipment.

With a length of 1.1 meters and weighing 160 kg, the Shark G2R is a reliable seahorse. It can carry up to 35 kg payload and operate down to 500 meters depth. Equipped with six thrusters, it can reach speeds up to 3 knots.

Advanced CNC kits ensure professional finish

Rovotics was formed in 2011 when a group of experienced ROV technical experts felt the market was lacking advanced systems that harnessed the latest technology, provided optimum reliability, quality and after sales support. In order to achieve the professional finish needed for the vehicles, Rovotics asked Diab to provide complete and fully painted CNC-processed buoyancy foam kits with a bolt-in-place design.

Diab were supplied a 3D-model in order to develop the programming for the 5-axis CNC machine. Diab also helped provide all the necessary buoyancy calculations to ensure that the ROV performed to design expectations.

"We received the desired buoyancy on time and we are currently exhibiting the ROV in Dubai. We are very happy with the finish of the buoyancy. It looks very good”, says Javier Gonzalez at Rovotics.

Read more about Rovotics www.rovotics.ae/