Hey there!

Do you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upSign in to MyDiab

Or log in with

Composite materials have been used in cryogenic applications for many years and offer solutions for reliable transport and safe storage of cryogenic gases such as LNG, LPG and ethylene.

Natural gas in a liquid state has an extremely low temperature range of -161 °C to -164 °C, placing high demands on the insulating components in LNG carriers, ground based storage tanks or fuel tanks for different gases.

This also applies to where mechanical forces are absorbed, such as at mounts or support bearings, where thermal bridges must be avoided. The very low thermal conductivity of especially our PVC foams results in less material needed to achieve the same insulation as traditional insulating material used.

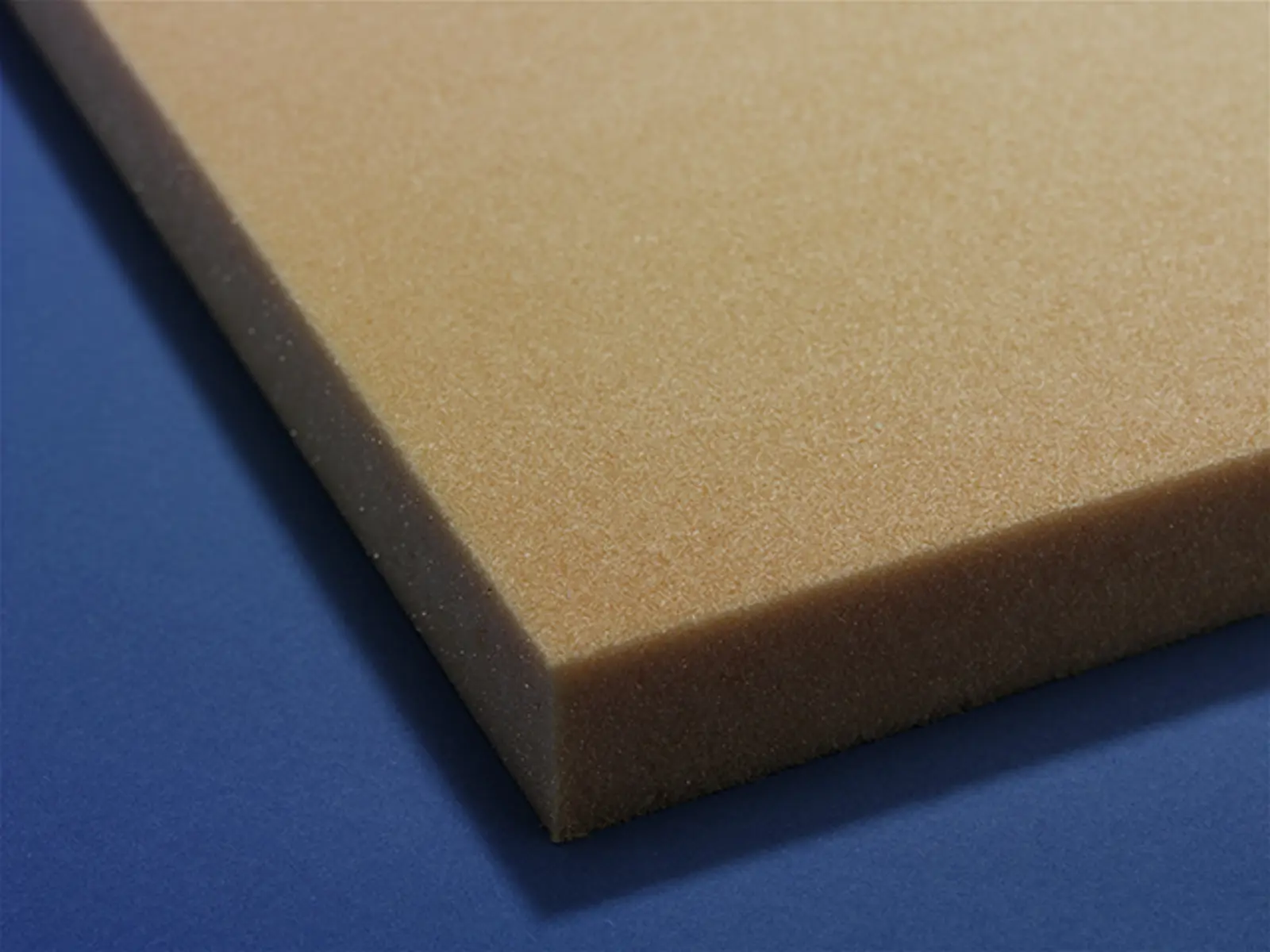

Our structural and insulating foams have closed cells to eliminate moisture absorption and the foam is able to absorb high mechanical forces and take high compression loads without being brittle. Other benefits include high creep resistance and chemical resistance. A fast and efficient installation can be achieved with big sheets and/or kitted solution.

Find and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.