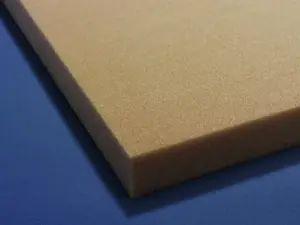

Divinycell H

Excellent mechanical properties to low weight.

Read moreDo you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upOr log in with

Divinycell PVC foam core materials are an all-purpose series used in multiple industries and available in a wide density range suitable for different manufacturing processes, such as closed moulding, including RTM and infusion and elevated temperature processing with prepreg.

Our PVC cores are engineered PVC foams that absorb and distribute the loads exposed to the sandwich, static or dynamic. They have a stable closed cell structure, resistant to water ingress, corrosion and decay.

The Divinycell series comes in grades H, HP, HM, HT, MC, MX and HCP with different features suitable for a variety of applications, and each grade has a broad range of densities. Divinycell PVC foam core range offers excellent mechanical properties and low weight. It is widely used and has a proven track record in virtually every application area employing sandwich composites, including wind, marine, industry, and transport.

PVC foams came into wider use as core materials in the 70’s. As sandwich structures began to be optimized, a need for a low-density, closed cell, consistent, moisture resistant foam core material was realized. Formulations has been refined over the years and the characteristics of PVC foams now fit the needs of not only the marine industry well. Our PVC foams are closed-cell, moisture resistant, and have excellent physical properties as well as very good thermal insulation.

The unique combination of cross linked polyurea and PVC yields impressive mechanical performance to a very low weight. The material does not contain hazardous plasticizers or substances and can easily be machined with wood working tools. The interaction of these polymers gives the foam core its unique characteristics. Although, the foam is a thermoset, it can still be thermoformed. In addition, it is resistant to many solvents including styrene and hydrocarbons, it is compatible with most adhesives and laminating resins including polyesters and epoxies. It is self-extinguishing and will not rot. Other inherent properties are excellent fatigue life and good dielectric properties.

Divinycell foam cores can be processed with all commonly used manufacturing methods like hand lay-up, vacuum infusion, RTM and also with prepregs.

The latest innovation Divinycell MC is a PVC foam with absolute lowest weight to mechanical properties. With a new manufacturing method, the cell size is reduced to a minimum allowing very low resin usage in lamination resulting in both weight and cost savings on the sandwich panel.

Comprehensive quality documentation and traceability for aerospace applications.

Read moreReduce cost, decrease weight, improve quality – get a competitive edge with the optimal finishing.

Find out moreImprove efficiency, lower your cost, increase quality – boost performance with pre-cut parts.

Find out moreFind and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our tools

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.