Standard kits

A rational, high quality kitting that meets your needs of speed and efficiency

Read moreDo you have any questions or are you ready to dig deeper into your projects with one of our experts? We are here for you.

Don't have an account?

Sign upOr log in with

Improve efficiency, lower cost and increase quality with pre-cut core material parts.

A Diab kit is a tailor-shaped set of core elements. The kit can consist of simple pre-cut core panels, or complex 3D shapes made with CNC routing. Each piece is pre-cut and then numbered to fit precisely into its designated place in the mould. Kits are designed based on your application’s requirements for weight, cost and quality. Our kit engineers take geometry and your manufacturing process into account when designing each kit. A kit drawing is supplied with each kit to define the assembly lay-up in the mould.

You can significantly streamline the manufacturing process and improve the quality of composite applications with pre-cut parts (kits). By eliminating the on-site cutting of sheets, you can reduce manufacturing time and save labour and material costs. With easy assembly and exact fit, you can constantly achieve high quality in less time.

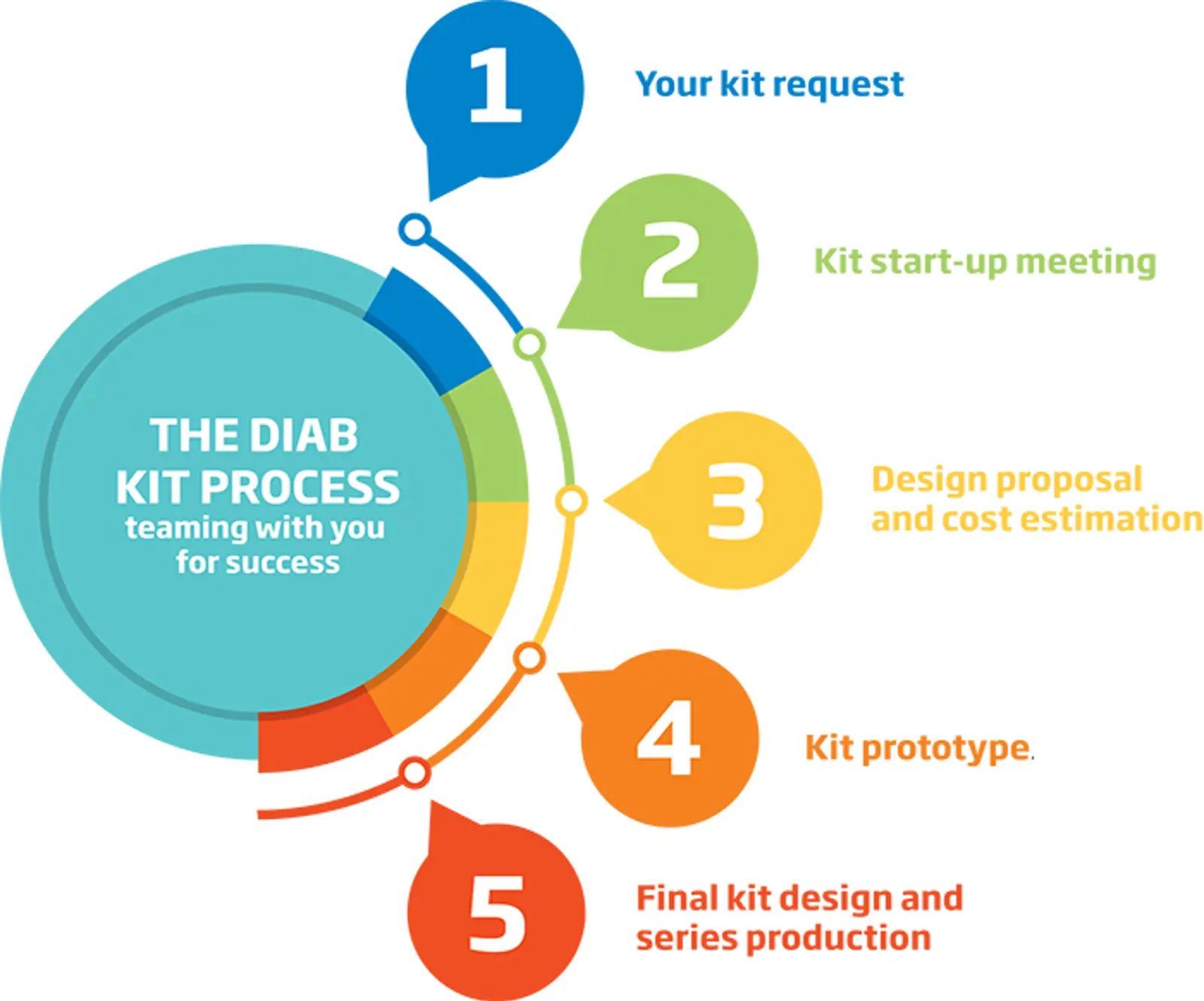

Diab is a world-leading supplier of sandwich composite solutions with long experience in developing kits. With in-depth technical knowledge in most manufacturing methods for composites, we understand what criteria are essential for the core kit to fit the purpose. We select the most appropriate from our wide selection of finishes for form or flow, based on the requirements. We design and produce our kits in-house, and we provide a direct connection between our engineering department and yours. Our experts are often on-site to discuss directly with you, take measurements, and note potential variations during the kit development phase. Together, we find the optimal solution.

Discussions early in the kit design phase will help ensure it meets all the requirements and expectations for performance, geometry and the manufacturing process. Based on this, our kit and production engineers decide what kit option is best for each case.

Standard kit is a good choice if your acceptable tolerances on the kit are higher and component weight is not super-critical.

Advanced kit is the optimal solution where light weight, low resin usage and highest surface finishing are crucial.

A rational, high quality kitting that meets your needs of speed and efficiency

Read moreFind and download certificates, datasheets and other documents here.

DownloadFind the tools and services you need to draw all the benefits from our materials.

See our toolsIf you can imagine it, our specialized consultants in CCG can probably help you build it.

Find out moreReduce cost, decrease weight, improve quality – get a competitive edge with the optimal finishing.

Find out more

To ensure that we give you the best experience on our website. Find out more about the cookies we use in our cookie policy.

Required

These cookies are required in order for the website to function normally.

Statistics

These cookies are used to collect statistical information.

Marketing

These cookies are used for marketing-related purposes.