Diab – Always at the core of your solution

What others say cannot be done, we do every day. Diab’s experience when it comes to optimize sandwich composite solutions is second to none.

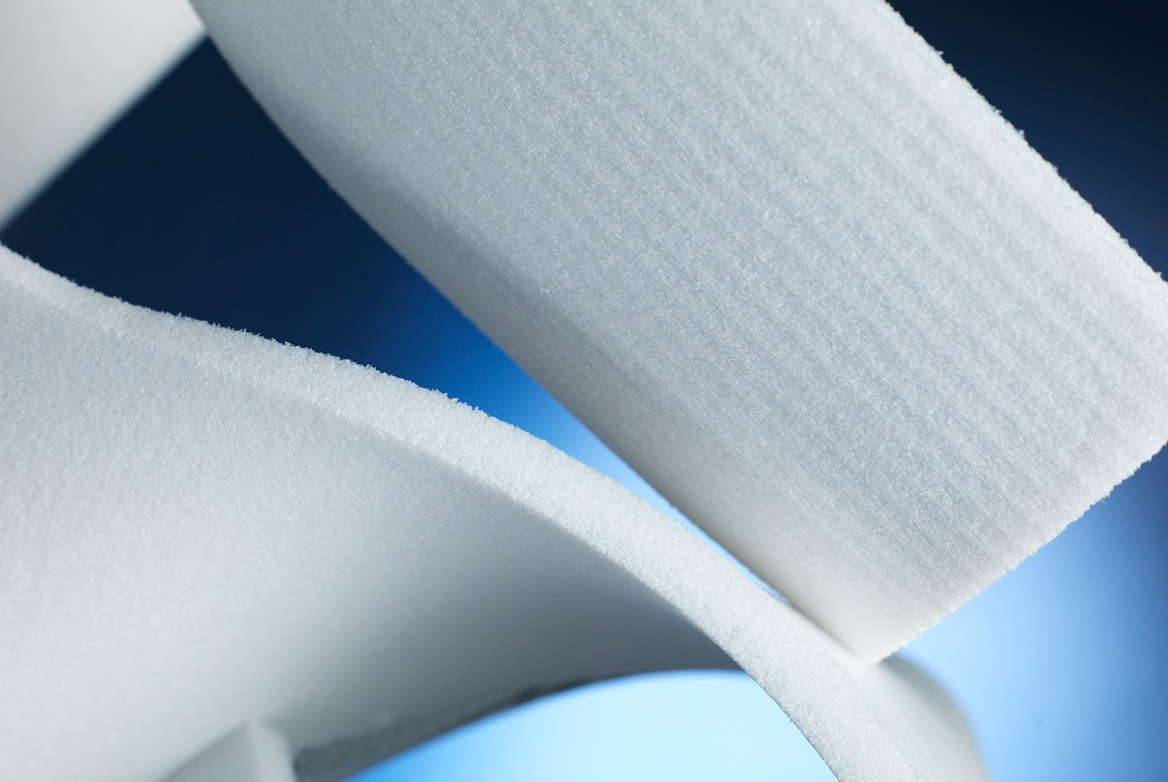

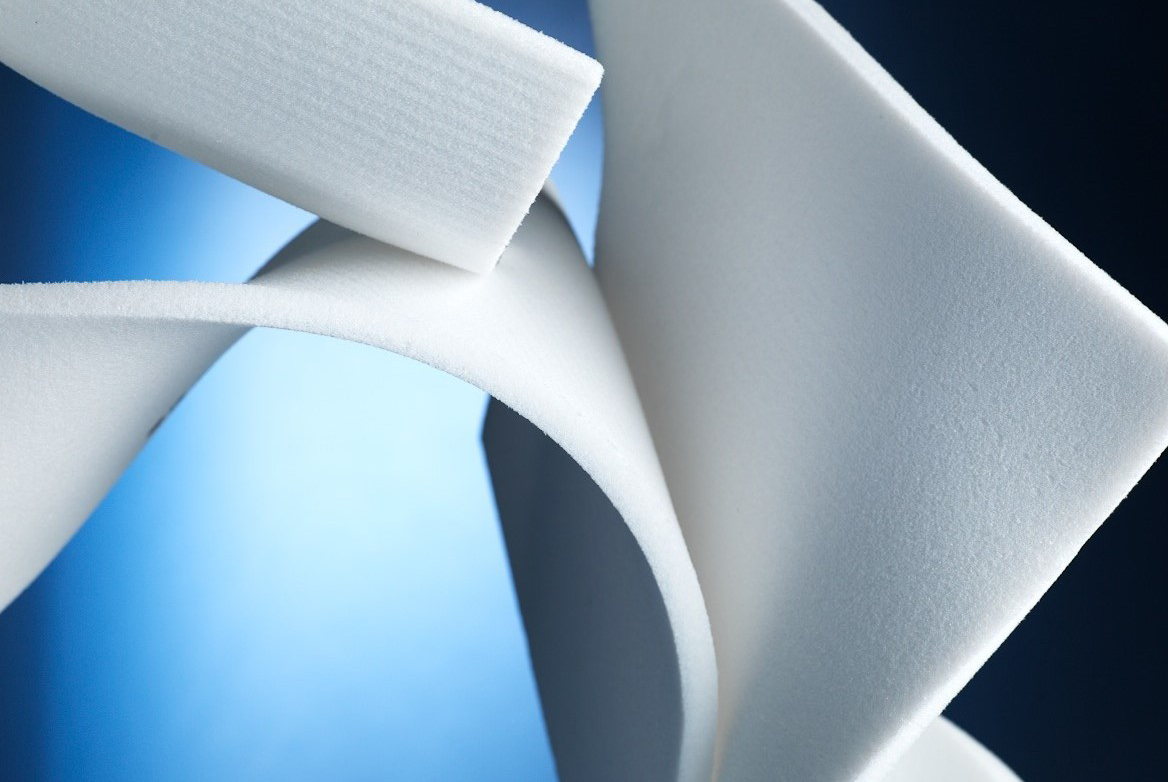

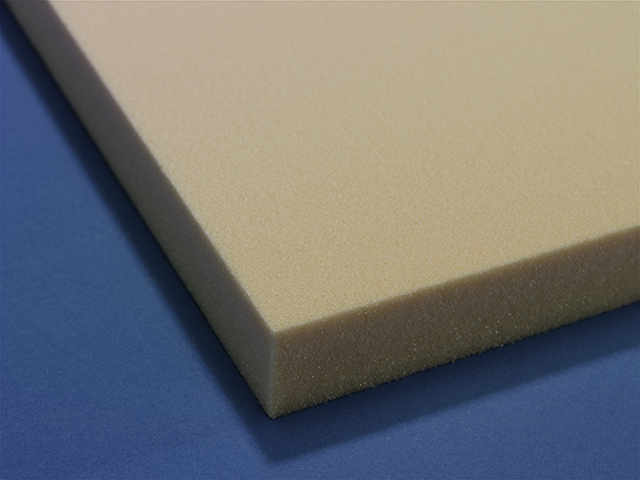

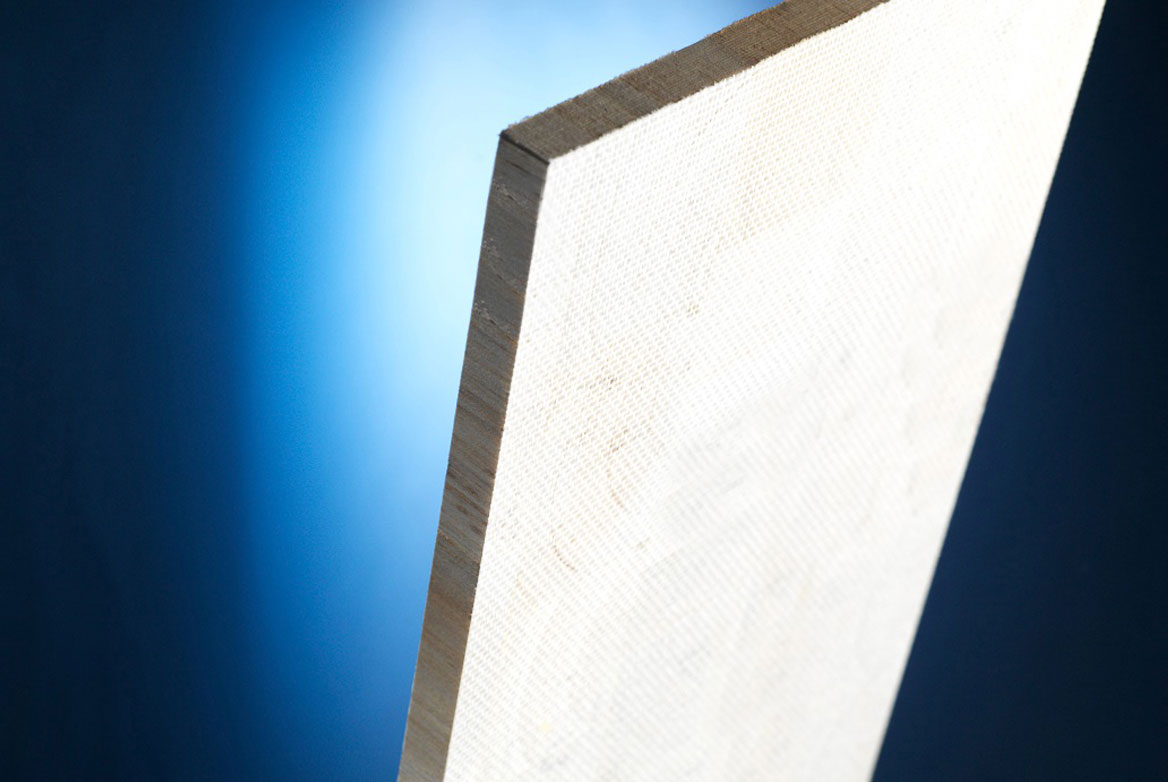

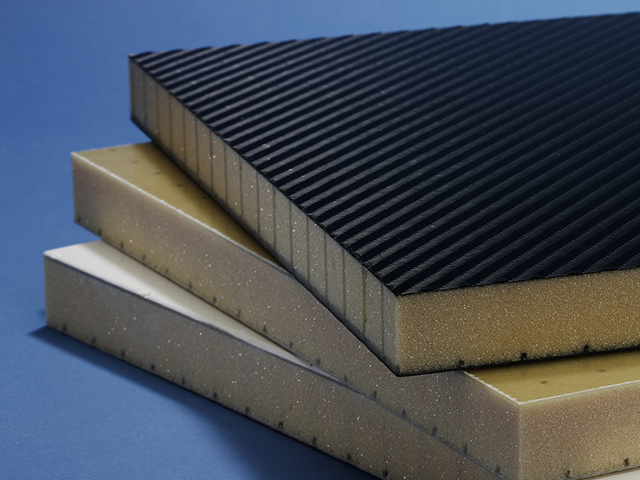

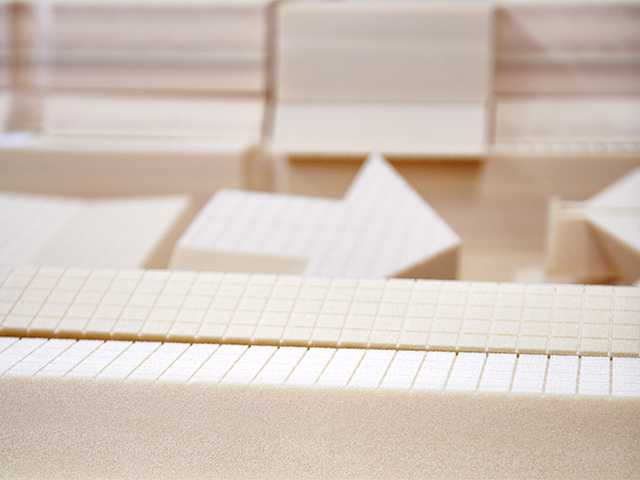

Since our start over 70 years ago, we have developed, improved and fine-tuned the technology and we know where it can be used to its best advantage. Today, Diab’s high-performance core materials can be found in applications all over the world, in industries like marine, aerospace, wind energy and transport, making them more competitive and sustainable. We produce our own material, ensuring a secure supply chain and achieving efficient and sustainable management. And we are always exploring new ways to improve our offering and help you make your products stronger, lighter and smarter.